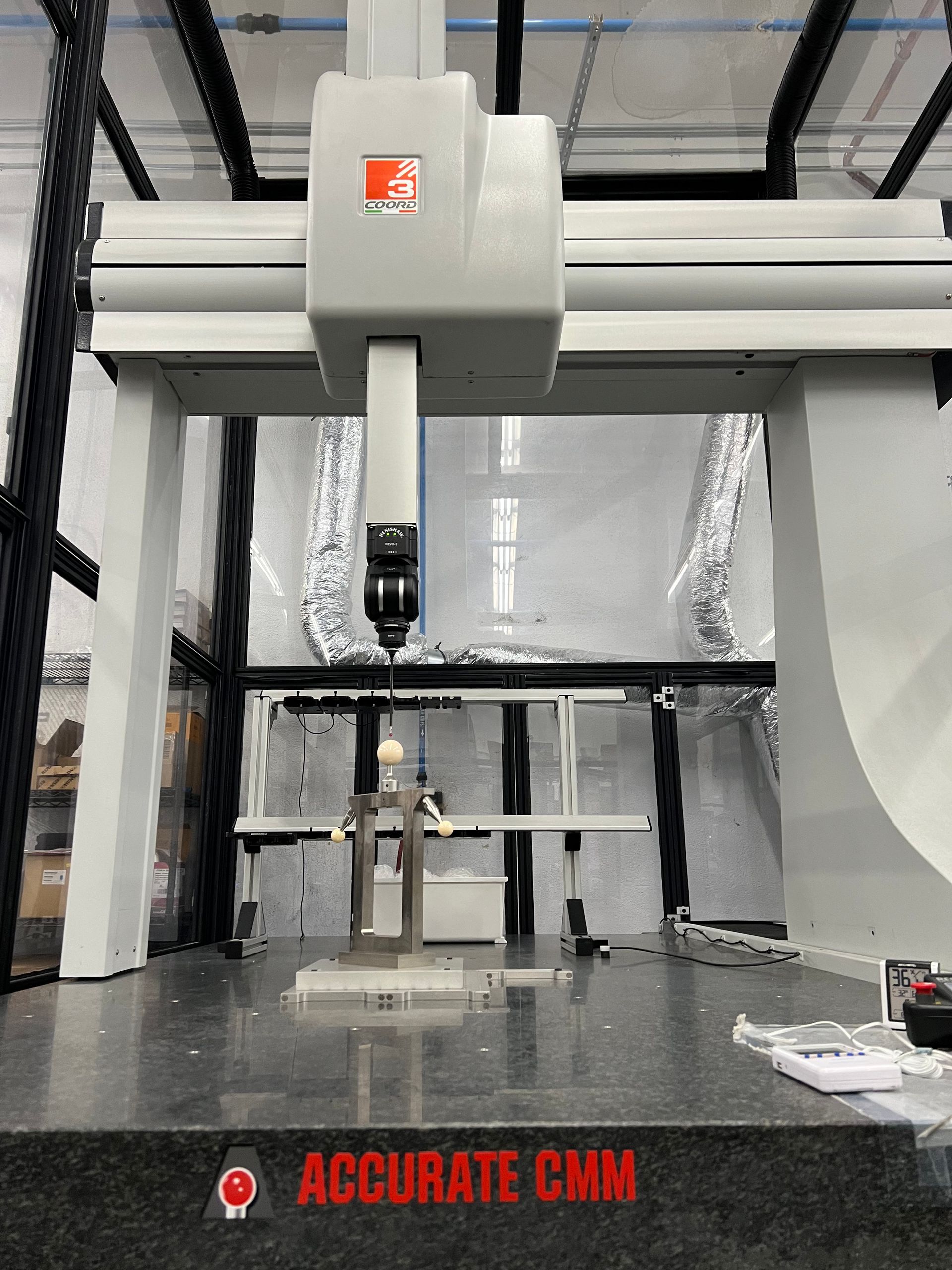

The revolutionary 5-axis technologies allows users to minimize dynamic errors while increasing measuring speeds and maintaining accuracy. By utilizing the sensor head to move around the part rather than the CMM structure.

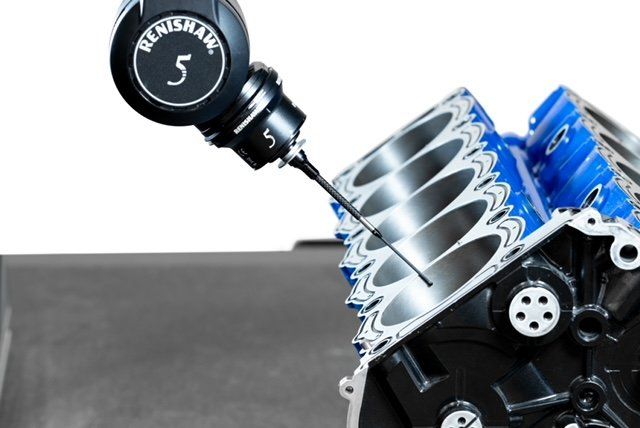

Revo- A REVO® system delivers high performance scanning, non-contact inspection and surface finish analysis on a single CMM.

The REVO system uses synchronized motion and 5-axis measurement technology to minimize the dynamic effects of CMM motion at ultra high measurement speeds.

This is achieved by letting the REVO-2 head do the fast demanding motion while the CMM moves in a linear slow fashion. The use of a flexible tip-sensing probe further adds to the system's accuracy and performance. The removable probe system, used in conjunction with a low cost changer, provides added system flexibility.

As a new installation or an accredited upgrade, the REVO® 5-axis measurement system offers:

Surface finish measurement and dimensional inspection.

15% to 50% cycle time savings.

Maximised throughput, minimised capital investment.

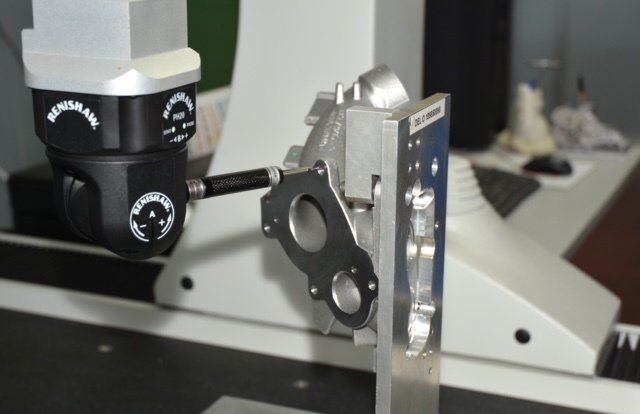

PH20- Unlike conventional touch-trigger measurement methods which rely on speeding up the motion of the CMM's 3 axes to measure quickly, PH20 utilises the head motion technology developed for the multi-award winning REVO system to minimise the dynamic errors of the CMM at higher measurement speeds.

PH20's unique ‘head touches' allow measurement points to be taken by moving only the head, rather than the CMM structure. Points can be taken faster, and with improved accuracy and repeatability.

Furthermore, 5-axis motion eliminates time spent indexing the head. Together these speed increases typically result in a 3-fold improvement in throughput over conventional systems.